The legislative developments approved in recent years in the field of circular economy and waste management pose a long list of obligations for the industrial and business sector. The main objective is to achieve a more sustainable and circular production model, applying new consumption and production patterns.

The main path is defined by the European framework, which at national level is transferred through Royal Decree 1055/2022 on Packaging and Packaging Waste, and Law 7/2022 on Waste and Contaminated Soil for a Circular Economy, both in force since 2022. This new legal framework represents a turning point in the management of packaging and its circularity, establishing new obligations and targets for companies.

And as if all these changes were not enough, last October the European Parliament approved the Proposal for a Regulation on packaging and packaging waste, which will force the current national legal framework to be updated.

Moving towards more sustainable packaging models brings with it ambitious challenges and opens up several fronts for companies: eco-design, reduction of hazardous substances in packaging, registration of product producers, new management costs, etc. All this while maintaining the functionality and performance of packaging.

While this path is neither easy nor cheap, industrial packaging plays an essential role in optimising logistics operations, and studies show that these interventions can be very beneficial in the medium to long term.

Effective design can improve space utilisation in warehouses and transport vehicles, reduce handling and shipping costs, minimise waste and improve a company’s corporate image.

It seems important to highlight these aspects, as in many industrial companies, and especially in SMEs with lower capacity, the economic profitability of this type of solution may be questioned. In any case, these are investments with a return, the negative effects of which end up being offset by all these advantages.

But what options are available to make our packaging more sustainable? First of all, we must be clear about the characteristics that make packaging sustainable, such as ease of handling, the use of materials with a low environmental impact or the ease with which it can be recycled or reused.

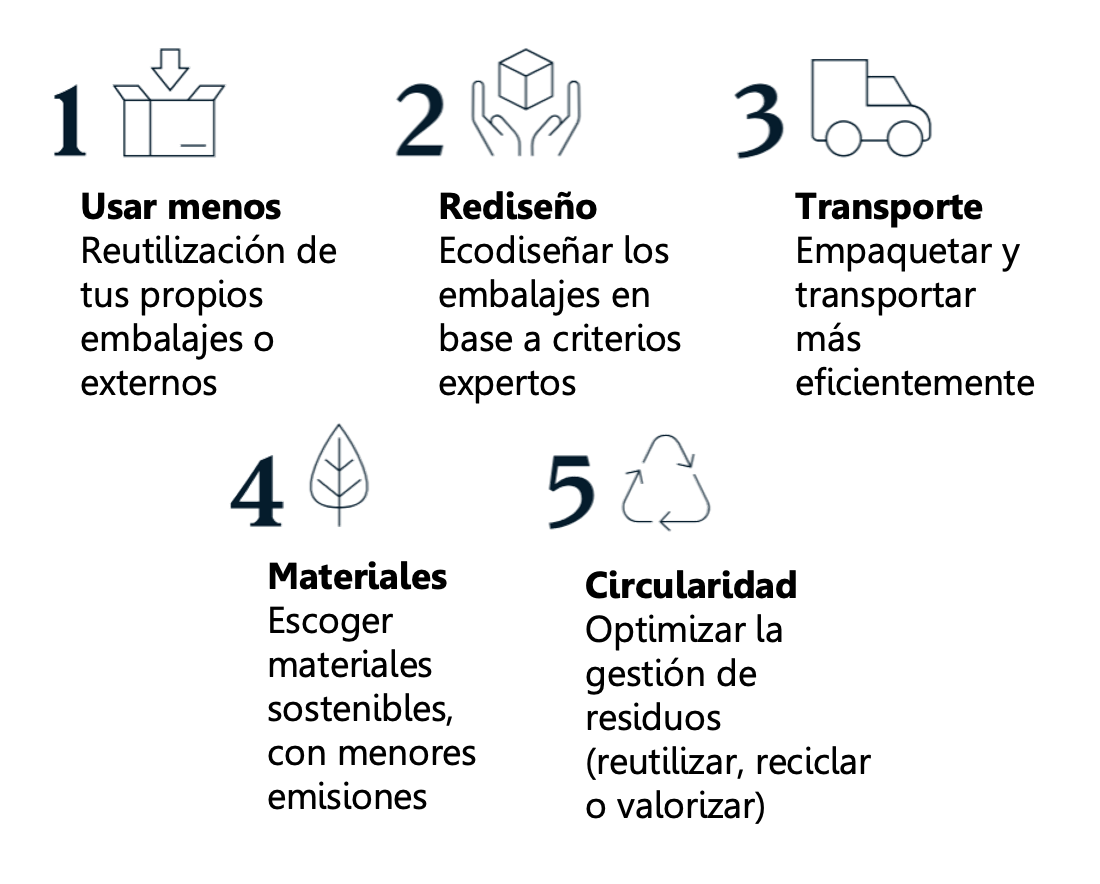

The design and implementation of sustainable packaging should incorporate a holistic approach based, according to the McKinsey Center for Sustainable Packaging, on the following five main levers of change:

In order to optimise the process, it is necessary to take into account the particularities of the goods to be packaged and look for solutions that both gain a competitive advantage and contribute to cost savings and improve the company’s sustainability.

The options are numerous today and include, among others:

- Incorporate green purchasing requirements that minimise the environmental impact of the packaging or materials purchased.

- Define criteria for the minimum content of reused or recycled raw materials in their packaging.

- Reduce or replace of adhesive tapes, labels or any other element limiting the recovery of the packaging.

- Use compostable materials that can decompose naturally and safely.

- Integrate recyclability criteria in the design phase, avoiding complex packaging, seeking to make it lighter, easier to recycle, etc.

- Seek reusable packaging options considering reverse logistics.

Source: Pacto Mundial Red Española

Innovation through automation and digitisation of processes also allows for a more efficient and optimised process. One of the advances in this regard is the incorporation of smart components or RFID tags, which can facilitate the traceability and tracking of operations in the supply chain.

Market demands are continually evolving and advancing, and companies must not only respond to legislative obligations, but also to the new requirements of their customers, who are increasingly demanding in terms of sustainability and circularity of the products they purchase.

In short, the change towards more sustainable packaging can be key to the success or failure of an industrial business and the achievement of such ambitious objectives is only possible through collaboration between all parties, innovation, a harmonised regulatory framework and anticipation.